Introduction of production process

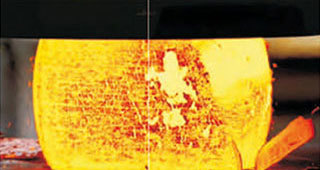

Hot working

A natural gas heating furnace that continuously operates, with precision and efficiency, to raise the temperature of the material block to the appropriate forging temperature.

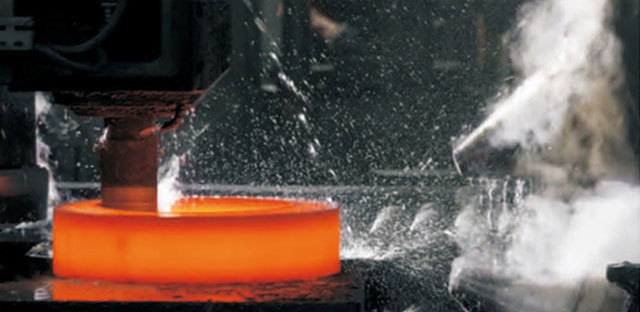

Forging and hammering

A forging production line composed of air hammer, ring rolling machine, and pressure unit, suitable for multi specification and small quantity manufacturing in the flange industry. Flexible production can easily complete customer orders and shorten delivery times.

Grinding ring

Rolling various types of seamless circular forgings to form rough blanks ensures product accuracy while saving costs, making the product more cost-effective.

Machining

The efficient production of fully CNC machining ensures surface smoothness and more precise product dimensions, ensuring consistency. The high-speed CNC drill introduced from Taiwan makes the bolt hole wall incredibly smooth and irresistible.

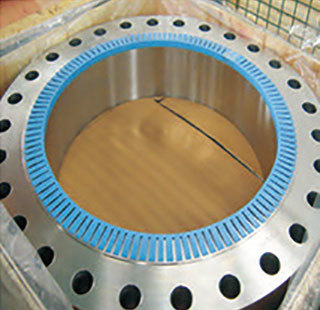

Antirust

Rust prevention treatment is applied to the machined flange surface, commonly used methods include oil coating, painting, galvanizing, and nitrous acid coating.

Rust prevention treatment is applied to the machined flange surface, commonly used methods include oil coating, painting, galvanizing, and nitrous acid coating.

Oil coating: the most commonly used anti rust treatment, convenient and practical.

Painting: black paint, yellow paint, blue paint, and others. Among them, black paint and yellow paint are commonly used methods, while blue paint and others are agreed upon according to customer specific requirements.

Galvanizing: Generally, hot-dip galvanizing is used to make the product more corrosion-resistant and rust proof, and it is executed according to the special requirements of the customer.

Applying nitrous acid: It is less commonly used and has a shorter rust prevention cycle, usually about 1-2 weeks, so it is more used in production turnover rather than shipping products. Unless the customer has such a request, it can be implemented after mutual agreement.

Packing

The sufficiently thick board ensures the firmness of the wooden box, and each layer of flange is equipped with partitions to prevent collision. The gaps are filled with extruded boards, making the entire packaging seamless and sturdy, ensuring that the product maintains consistent high quality from the factory to the customer's hands.